I. Introduction

1. Overview of laser cutting machines

Laser cutting machines have revolutionized the manufacturing and creative industries by offering precise and efficient cutting capabilities for a wide range of materials. These machines utilize a high-powered laser beam to cut, engrave, or mark materials such as metals, plastics, wood, and textiles. The technology behind laser cutting is continually evolving, with advancements in laser power, accuracy, and versatility making these machines an indispensable tool in various sectors, including automotive, aerospace, electronics, and even fashion.

2. Importance of accessories for enhancing performance and efficiency

One crucial aspect that significantly impacts the performance and efficiency of laser cutting machines is the selection and maintenance of accessories. Accessories for laser cutting machines, such as lenses, nozzles, cooling systems, and safety equipment, play a vital role in enhancing the machine's capabilities and ensuring high-quality output. High-quality accessories not only improve the precision and speed of the cutting process but also contribute to the machine's longevity and safety for users.

3. Importance of accessories for enhancing performance and efficiency

- Optical components: Mirrors, lenses, and beam delivery systems that control and focus the laser beam.

- Material handling accessories: Cutting beds, rotary attachments, and hold-down systems that support and position the workpiece.

- Safety equipment: Protective eyewear, fume extractors, and fire suppression systems that ensure operator safety and environmental compliance.

- Maintenance tools: Cleaning kits, alignment tools, and replacement parts that keep the machine in optimal condition.

- Software and control systems: CAD/CAM software and interface modules that enhance machine control and design capabilities.

In this guide, we will explore the essential accessories for laser cutting machines, their types, and their importance in the overall performance and safety of the equipment. From understanding the different types of laser lenses to selecting appropriate safety gear, this comprehensive overview aims to provide valuable insights for both novice and experienced users of laser cutting technology.

II. Essential Accessories for Laser Cutting Machines

1. Laser Lenses

Laser lenses are critical components in laser cutting machines, as they focus the laser beam onto the material, influencing the precision and quality of the cut. There are several types of laser lenses, each serving different purposes:

- Plano-Convex Lenses: These lenses have a flat surface on one side and a convex surface on the other, helping to focus the laser beam into a fine point. They are widely used for their versatility in various cutting and engraving applications.

- Meniscus Lenses: These lenses have a curved surface on both sides, one concave and the other convex. Meniscus lenses are designed to reduce spherical aberrations and provide a smaller focal spot, resulting in higher precision cutting, particularly useful for detailed work.

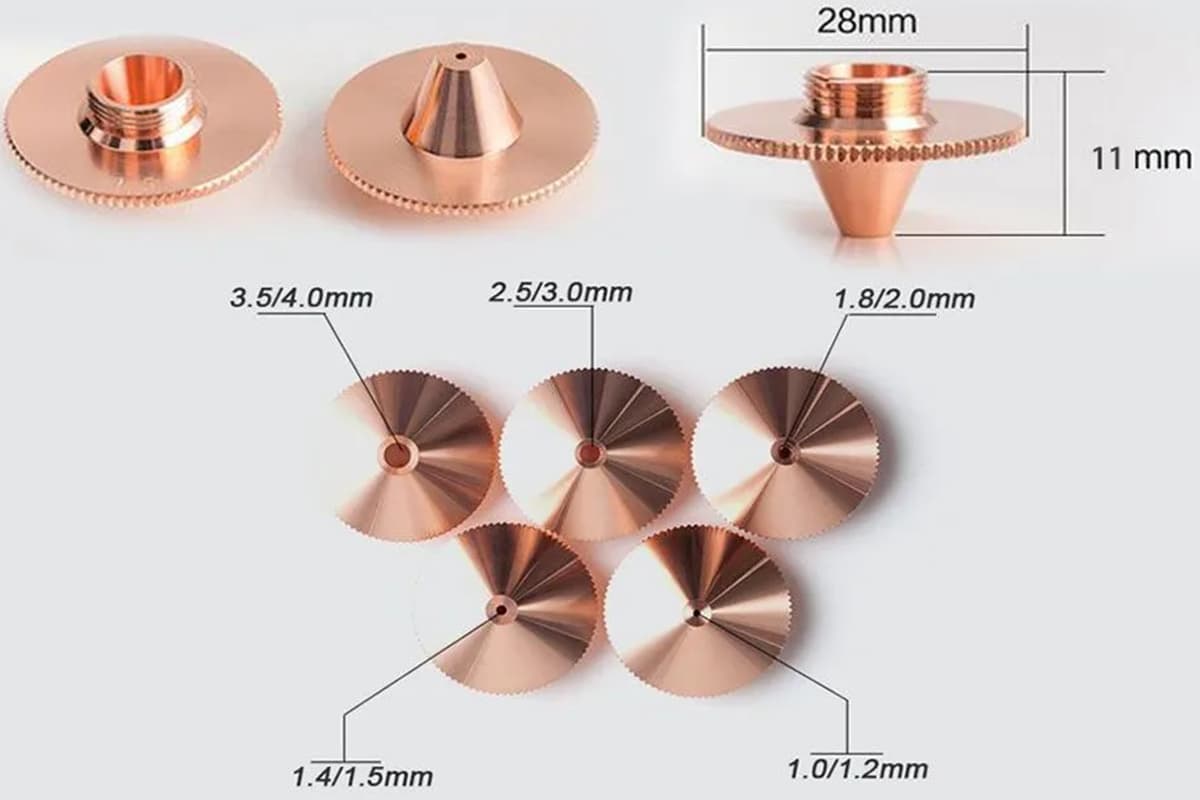

2. Laser Nozzles

Laser nozzles are another essential accessory, playing a key role in the efficiency and quality of the cutting process. The nozzle directs the laser beam and assists in the expulsion of molten material from the cut. There are different types of nozzles available, each designed for specific applications:

- Single-Layer Nozzles: These are simpler in design and are typically used for cutting thinner materials. They provide a direct path for the laser beam, offering decent control over the cutting process.

- Double-Layer Nozzles: These nozzles have a more complex design and are used for thicker materials. They help in better gas flow management, which improves the cooling of the cut area and reduces the risk of material distortion.

3. Laser Tubes

The laser tube is the source of the laser beam in the cutting machine. There are different types of laser tubes, each suited for specific applications:

- CO2 Laser Tubes: Commonly used in many industrial and hobbyist machines, CO2 laser tubes are versatile and can cut a wide range of materials, including wood, acrylic, and fabric. They are known for their efficiency and cost-effectiveness.

- Fiber Laser Tubes: These are more powerful and are used for cutting metals. Fiber lasers offer high precision and speed, making them ideal for industrial applications where detail and efficiency are critical.

4. Cooling Systems

Cooling systems are crucial for maintaining the optimal operating temperature of laser cutting machines. They prevent overheating, which can damage the laser tube and other components. The two main types of cooling systems are:

- Water Chillers: These systems circulate water around the laser tube to dissipate heat. Water chillers are effective and commonly used in industrial settings due to their ability to handle high-power lasers.

- Air Cooling: Air cooling systems use fans to blow air over the laser tube. While less efficient than water chillers, they are simpler and more affordable, often used in smaller machines.

III. Safety Accessories

1. Protective Eyewear

Protective eyewear is an essential safety accessory for anyone operating a laser cutting machine. The intense light and potential reflections from the laser beam can cause serious eye injuries, even blindness. Therefore, wearing appropriate protective eyewear is crucial to safeguard the eyes.

There are different types of protective eyewear designed for use with laser machines:

- Laser Safety Glasses: These glasses are specifically designed to protect against the wavelengths of light emitted by the laser. It's important to select glasses that are rated for the specific type of laser being used, whether it's CO2, fiber, or diode, as each type emits light at different wavelengths.

- Goggles: For environments where full protection is necessary, laser safety goggles can offer additional coverage around the eyes, providing enhanced safety.

2. Laser Safety Curtains and Enclosures

To further ensure the safety of operators and bystanders, laser safety curtains and enclosures are commonly used. These accessories help contain the laser beam within a designated area, preventing accidental exposure to laser radiation.

- Laser Safety Curtains: These are flexible barriers made from materials that can absorb or block laser radiation. They are used to create safe zones around the laser machine, especially in open or multi-use areas.

- Laser Enclosures: These are rigid structures that completely enclose the laser cutting area. Enclosures provide the highest level of safety by ensuring that no laser radiation escapes, protecting both operators and the surrounding environment.

3. Fume Extractors

Laser cutting and engraving processes often produce fumes and particulate matter, which can be harmful if inhaled. Fume extractors are essential accessories that help maintain air quality in the workspace.

- Importance of Air Quality Management: Inhaling fumes from materials like plastics, metals, or treated wood can pose health risks, including respiratory issues and other long-term health effects. Fume extractors help to capture and filter out harmful substances from the air, making the working environment safer.

- Types of Extraction Systems: There are various fume extraction systems available, ranging from small, portable units to larger, centralized systems. The choice of system depends on the size of the laser cutting operation and the materials being processed. Key features to consider include the type of filtration system (e.g., HEPA filters) and the airflow capacity.

4. Emergency Stop Buttons

Emergency stop buttons provide a quick way to halt machine operation in case of an emergency:

- Placement: Easily accessible locations around the machine and work area

- Function: Immediately cuts power to the laser and all moving parts

- Features:

- Large, clearly marked buttons

- Latching mechanism to prevent accidental reactivation

- Integration with machine control systems

- Importance:

- Allows for rapid response to dangerous situations

- Prevents injuries and equipment damage

- Required by safety standards in most regions

IV. Consumable Accessories

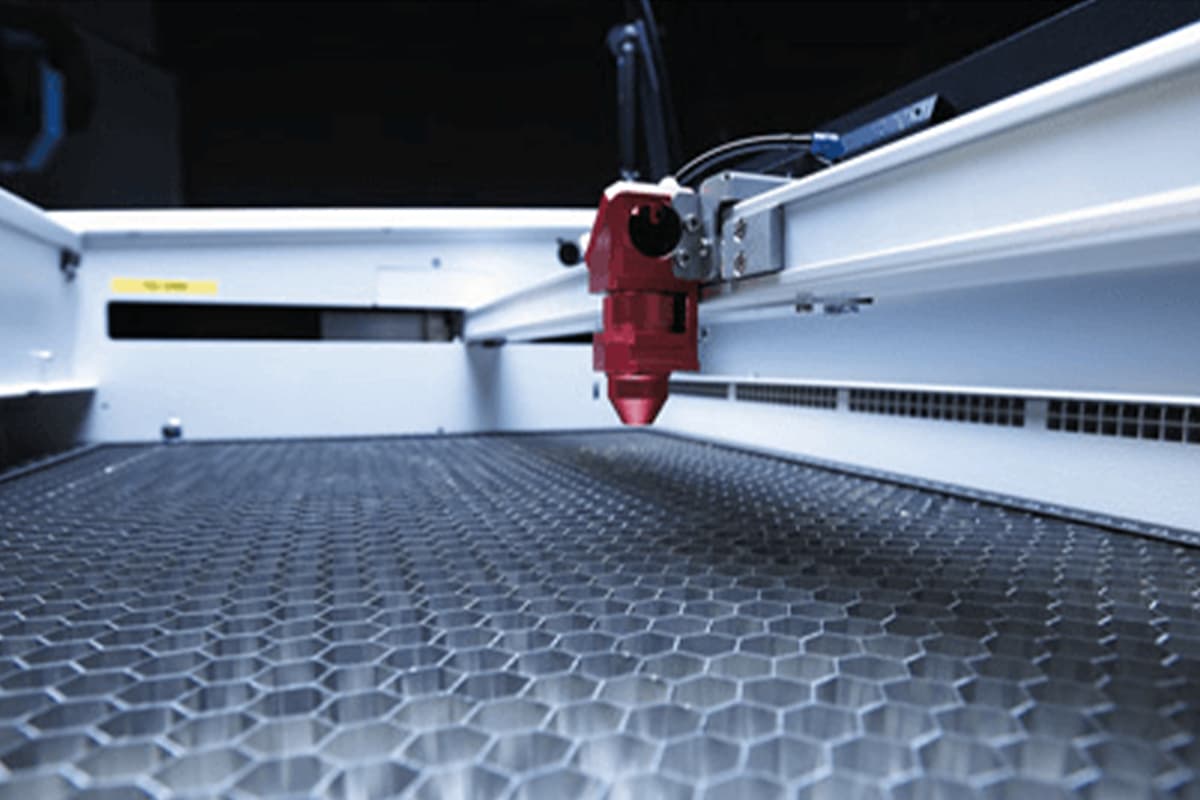

1. Cutting Beds and Mats

Cutting beds and mats are essential accessories for laser cutting machines, as they provide a stable surface for materials during the cutting process. These accessories not only help protect the machine's components but also improve the quality of the cuts.

- Different Materials and Their Uses: Cutting beds can be made from various materials, such as honeycomb grids, aluminum, or steel. Each type serves specific purposes:

- Honeycomb Grids: These are commonly used for materials that benefit from minimal contact with the cutting surface, such as acrylic or fabric, as they help reduce the reflection of the laser beam and minimize burning on the backside of the material.

- Aluminum and Steel Beds: These are more robust and are used for cutting harder materials like metals. They provide strong support and can withstand the heat and force of the cutting process.

- Importance in Protecting the Machine and Improving Cut Quality: A well-maintained cutting bed can prevent damage to the laser machine's optics and other components by ensuring that debris and offcuts do not accumulate excessively. Additionally, using the right type of cutting bed can enhance the quality of cuts, reducing the need for post-processing.

2. Reflective Mirrors

Reflective mirrors are used in some laser cutting systems to direct the laser beam from the source to the cutting head. The quality and alignment of these mirrors are crucial for maintaining the power and accuracy of the laser.

- Types and Materials: Mirrors used in laser systems can be made from materials like silicon, molybdenum, or copper, often coated with a reflective layer to increase efficiency.

- Silicon Mirrors: These are lightweight and provide high reflectivity, making them ideal for applications where weight is a concern.

- Molybdenum and Copper Mirrors: These are more durable and resistant to heat, suitable for high-power laser systems.

- Maintenance Tips for Optimal Performance: Regular cleaning and inspection of mirrors are necessary to ensure they remain free of contaminants that can scatter the laser beam and reduce its power. Proper alignment is also critical, as misaligned mirrors can lead to a loss of cutting precision and efficiency.

3. Alignment Tools

Proper alignment of the laser beam is essential for achieving accurate cuts and preventing damage to the machine. Alignment tools are used to ensure that the laser beam is correctly aligned with the cutting path.

- Importance of Proper Alignment: Misalignment can result in uneven cuts, reduced cutting speed, and increased wear on the machine. It can also lead to safety hazards if the beam is not properly contained.

- Types of Alignment Tools: There are various tools available for aligning laser beams, including:

- Laser Alignment Targets: These are used to visually inspect and adjust the beam path, ensuring it is properly centered.

- Beam Alignment Kits: These kits typically include a range of tools for precise adjustment and calibration, such as adjustable mounts and positioning aids.

4. Additional Safety Considerations

- Enclosures and interlocks: Prevent access to the cutting area during operation

- Warning signs and labels: Clearly communicate hazards and safety requirements

- Personal protective equipment (PPE): Includes gloves, protective clothing, and respiratory protection when necessary

- Safety training programs: Ensure all operators are well-versed in safety procedures and equipment use

V. Software and Digital Accessories

1. Design Software

Design software plays a critical role in preparing files for laser cutting. It allows users to create, edit, and optimize designs before they are sent to the laser cutter. There are several popular software options, each offering unique features that benefit laser cutting:

- Adobe Illustrator: A widely used vector graphic design software, Adobe Illustrator is popular among designers and makers for its versatility and comprehensive set of tools. It allows users to create intricate designs with precision, which can then be converted into paths for laser cutting.

- CorelDRAW: Another powerful vector graphic design tool, CorelDRAW is known for its user-friendly interface and rich feature set. It is particularly favored for its ability to handle both vector and raster graphics, making it versatile for various laser cutting projects.

- AutoCAD: While primarily used for 2D and 3D drafting, AutoCAD is also valuable for laser cutting, especially for technical and engineering drawings. It supports precise measurements and detailed design specifications, which are crucial for complex projects.

- CAM software: Translates CAD designs into machine instructions. Optimizes cutting paths and machine parameters. Examples include LaserCAD, LightBurn, and RDWorks.

- Inkscape: A free and open-source vector graphic editor, Inkscape is a great option for those looking for a cost-effective solution. It offers many of the features found in commercial software and supports various file formats suitable for laser cutting.

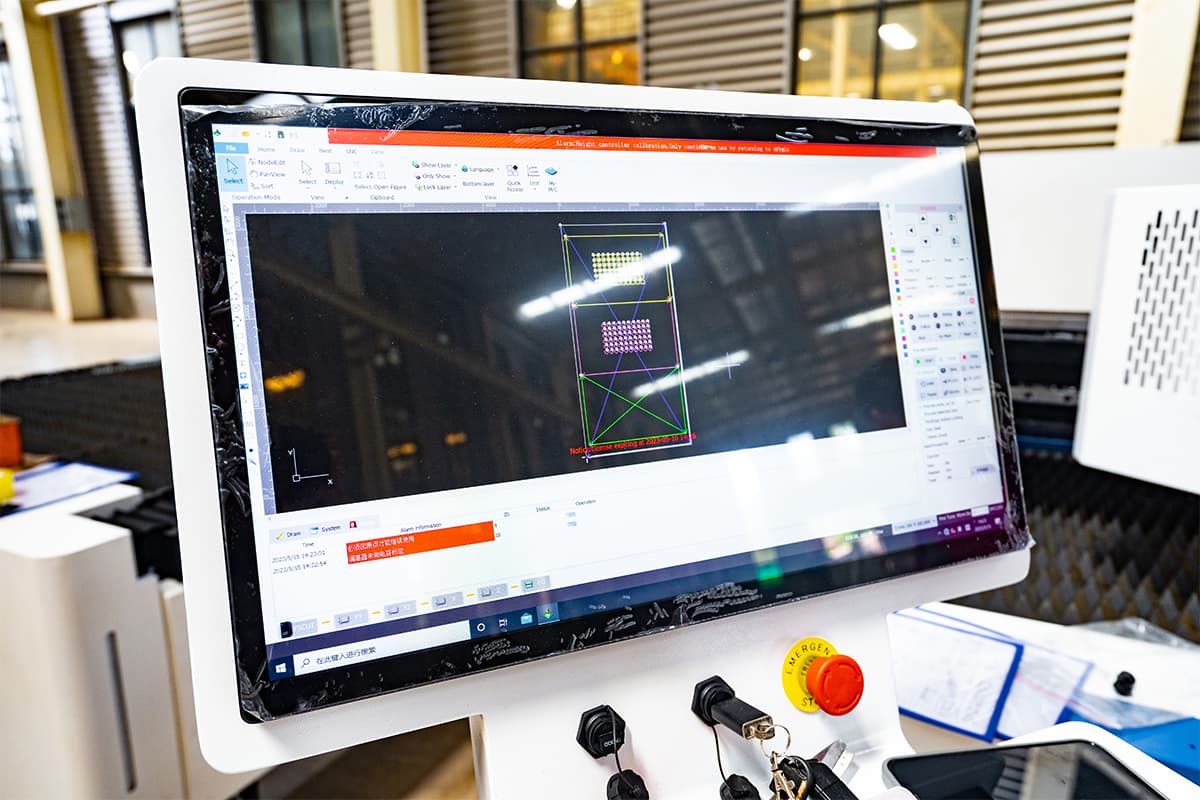

2. Control Software

Control software interfaces with the laser cutting machine, allowing users to manage the cutting process. This software is crucial for translating design files into machine commands and optimizing the cutting path.

- Integration with Laser Cutting Machines: Good control software ensures smooth communication between the design software and the laser cutter. It translates the design into a series of movements and settings (such as speed and power) that the machine follows.

- User-Friendly Interfaces and Features: Control software often includes features like:

- Job Preview: Allows users to see a simulation of the cutting process, helping to avoid mistakes and optimize material usage.

- Parameter Settings: Lets users adjust cutting parameters such as speed, power, and frequency, depending on the material and desired outcome.

- Layer Management: Enables the organization of different parts of the design into layers, which can be cut or engraved separately. This is particularly useful for projects involving multiple materials or processes.

VI. Maintenance and Cleaning Accessories

1. Lens cleaning kits

Lens cleaning kits are vital for maintaining the optical components of the laser cutter:

- Contents typically include:

- Lens cleaning solution (usually methanol or specialized optical cleaner)

- Lint-free wipes or cotton swabs

- Lens cleaning tissues

- Compressed air cans for dust removal

- Importance:

- Keeps lenses free from debris, ensuring optimal laser focus

- Prevents damage to expensive optical components

- Maintains cutting quality and efficiency

- Clean lenses regularly, ideally before each use or shift

- Use gentle, circular motions when cleaning

- Always handle lenses with care to avoid scratches or damage

2. Lubricants and coolants

Proper lubrication and cooling are essential for the mechanical and thermal management of laser cutters:

- Lubricants:

- Used for moving parts like linear guides and bearings

- Helps reduce wear and extend component life

- Specific types may be recommended by the manufacturer

- Coolants:

- Used in closed-loop cooling systems for laser tubes and other components

- Helps maintain optimal operating temperatures

- Often requires regular checking and replenishment

Best practices:

- Follow manufacturer guidelines for lubrication schedules and coolant maintenance

- Use only recommended lubricants and coolants to avoid compatibility issues

- Regularly check coolant levels and quality

VII. FAQs

Q1: What are the best accessories for improving cut quality?

Improving cut quality often involves optimizing several aspects of the laser cutting process, including the choice of accessories:

- High-Quality Lenses: Using high-quality, clean laser lenses ensures that the laser beam is properly focused, resulting in cleaner cuts. Regular maintenance and replacement of lenses are crucial for maintaining optimal performance.

- Appropriate Nozzles: Selecting the right type of nozzle for the material and cutting task can significantly improve cut quality. Double-layer nozzles, for instance, are often better for thicker materials as they provide better gas flow and reduce the risk of material burns.

- Proper Cooling Systems: Effective cooling systems, such as water chillers, help maintain a stable temperature for the laser tube, preventing overheating and ensuring consistent performance.

- Stable Cutting Beds: Using the appropriate cutting bed, such as a honeycomb grid, can reduce back reflections and ensure smoother cuts, especially for delicate materials.

Q2: How do you maintain your laser cutting machine accessories?

Regular maintenance is essential for keeping your laser cutting machine and its accessories in top condition. Here are some general tips:

- Lenses and Mirrors: Regularly clean lenses and mirrors with appropriate cleaning solutions and soft cloths to prevent dust and debris buildup, which can scatter the laser beam and reduce efficiency.

- Nozzles: Inspect nozzles regularly for signs of wear or clogging. Clean or replace them as needed to maintain optimal gas flow and cutting quality.

- Cooling Systems: Check the water levels and cleanliness of water in chillers, and ensure that fans or other cooling mechanisms are functioning properly. Regular maintenance helps prevent overheating and extends the lifespan of the laser tube.

- Fume Extractors: Replace filters in fume extractors regularly to maintain efficient air quality management. Ensure that the extraction system is properly sealed and free from blockages.

VIII. Conclusion

This guide has covered the essential accessories for laser cutting machines, safety considerations, and common maintenance practices. Whether you are a novice or an experienced user, this information is intended to help you achieve the best possible results from your laser cutting equipment.

As a sheet metal manufacturer with over 20 years of experience in producing laser cutting machines, we, ADH Machine Tool, understand the importance of high-quality accessories for cutting performance.

If you are looking for top-notch laser cutting machines or related accessories, feel free to contact us anytime. Our professional team is ready to provide you with customized solutions, helping you achieve success in the laser cutting field.Â

Swim Vest,Swim Vest For Man,Swim Vest For Women,Swim Vest For Child

ZHOUSHAN SKYTOP COMMODITY CO., LTD. , https://www.bodyboard.com.cn