Invented in 1970’s, water-assisted injection molding (WAIM) is one of the special injection molding methods beyond traditional methods. The concept was developed from gas-assisted injection molding (GAIM). Both technologies were derived to reduce resin cost and better product quality. However, WAIM has some benefits over GAIM such as more even wall thickness, shorter cycle time, lower medium cost, etc.

Although water-assisted injection molding is efficient in reducing material cost and improving product quality, there are still many challenges to overcome. In addition to extra cost, the control of process conditions is also not easy. Some usual defects are fingering effect, blow-through, surface glossy, hesitation mark, switchover mark, and fiber exposure. Since the process is so complex, it may take a significant number of trials to meet the product quality.

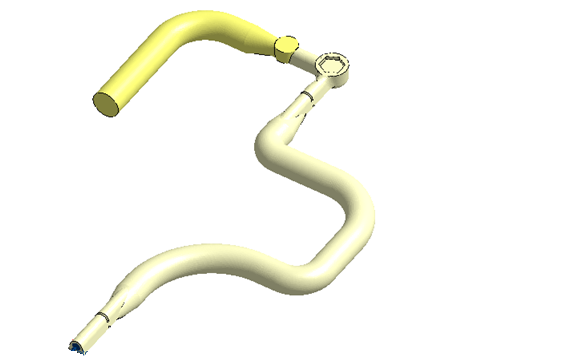

Fig. 1 Â A tube case with overflow region in yellow (left) Â Water and melt front (right)

With Moldex3D’s WAIM module, it provides an effective way for design changes. By predicting flow penetration behavior in three dimensions, the potential problems can be diagnosed prior to mold making stage which can help save developing time and cost. For more information about WAIM, please refer to the conference paper  “Water-Assisted Injection Molding: Validation of 3D Simulations by Experimental Data†or visit our Solution Add-on page for more in-depth features.

Conveyor Belts & Transport Devices

Conveyor belts and transport devices play a pivotal role in the efficient and seamless operation of injection molding machines. Their function is critical in the post-molding process, ensuring that plastic products are smoothly transported from the molding machine to the next stage of production or packaging.

In the context of injection molding, conveyor belts serve as the lifeline of the production line. Their primary function is to convey the molded plastic parts from the mold cavity to a designated area for further processing or packaging. This crucial step not only enhances the overall efficiency of the operation but also ensures that the products are handled gently and without damage.

One key aspect of conveyor belts is their sturdiness and durability. Made from robust materials, these belts are designed to withstand the rigorous demands of a busy production environment. They can handle heavy loads and resist wear and tear, even under continuous use. This ensures that the conveyor belts maintain their performance level for an extended period, reducing the need for frequent replacements or repairs.

Moreover, the ease of installation and integration is another noteworthy feature of conveyor belts. They can be easily fitted into existing production lines, minimizing downtime and disruption to the production process. Manufacturers can also customize the conveyor belts to fit their specific needs, such as varying belt lengths, widths, and speeds. This flexibility allows for seamless integration with different injection molding machines and production setups.

The efficiency of conveyor belts is another aspect that cannot be overstated. By quickly and efficiently transporting the plastic products, they help to maintain a high output rate and minimize downtime. This not only improves the overall productivity of the manufacturing process but also helps to reduce costs associated with labor and wasted materials.

Additionally, conveyor belts also contribute to the safety of the production environment. By automating the transportation of plastic products, they eliminate the need for manual handling, reducing the risk of accidents and injuries. This is especially beneficial in high-volume production environments where manual handling can be labor-intensive and prone to human error.

In conclusion, conveyor belts and transport devices are integral to the efficient operation of injection molding machines. Their sturdiness, ease of installation, efficiency, and safety features contribute significantly to the overall performance and profitability of the manufacturing process. As technology continues to evolve, conveyor belts are likely to become even more advanced and efficient, further enhancing the capabilities of injection molding machines and the plastics manufacturing industry.

Plastic Product Conveyor Belt,High Quality Conveyor Belt,Injection Molding Machine Conveyor Belt,High quality drive Belt

Ningbo Outai Plastic Machinery Technology Co.,Ltd , https://www.outacmachine.com